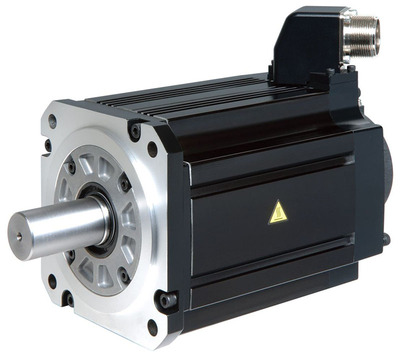

Servo motors are commonly used in CNC (Computer Numerical Control) machines as they provide precise and accurate positioning control, high torque, and fast response times. CNC machines are used in manufacturing processes to cut, drill, and shape materials such as metal, wood, and plastic.

The use of servo motors in CNC machines enables precise control of the motion and positioning of the cutting tool, which is critical to achieving accurate and repeatable cuts. Servo motors work by receiving a signal from the CNC controller that tells them how much to rotate, and they adjust their speed and torque accordingly to achieve the desired position.

In addition to providing precise positioning control, servo motors also offer other benefits for CNC machines, including:

- High torque: Servo motors can provide high torque at low speeds, which is important for cutting through tough materials.

- Fast response times: Servo motors can quickly respond to changes in the control signal, allowing for fast and precise movement of the cutting tool.

- Reduced vibration: Servo motors are designed to reduce vibration and maintain stability during operation, which can improve the quality of the cuts and prolong the life of the machine.

Overall, the use of servo motors in CNC machines has revolutionized manufacturing processes, enabling faster, more accurate, and more efficient production of a wide range of products.